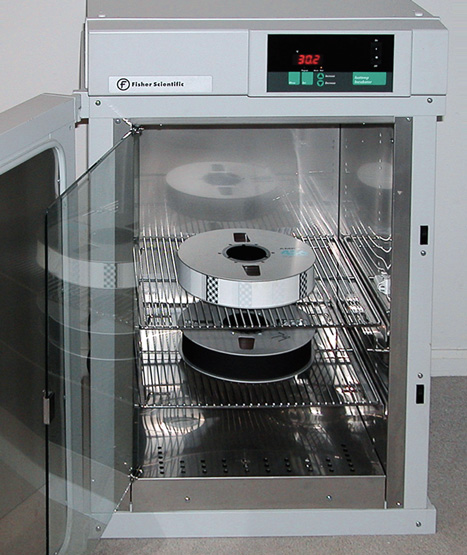

We do not trust your tape’s restoration to food dehydrators, which can fluctuate up to 15 degrees during the heating cycle with no reliable target temperature. At Sonicraft A2DX Lab we carefully selected scientifically designed professional-grade heating apparatus that provide a more precise and safe approach to restoration:

Fisher Scientific Incubator

Grieve Oven

All Reel Sizes: Both the Fisher and the Grieve accommodate up to 16″ reels of 2″ tape with ample space for optimal airflow.

We gently inspect your reel(s) for signs of Sticky Shed Syndrome. If confirmed, we schedule a bake session timed to your transfer appointment—keeping the tape at peak playability.

The tape is exposed to low, controlled heat for a carefully calculated duration. This process temporarily re-stabilizes the binder, making the tape safe to wind and play.

The most careful step of the restoration process is the first unwind. We re-tension the tape with undivided focus to make sure the incubation was successful and to be sure the tape is not suffering other restoration concerns such as adhesion syndrome or destabilization.

Once safely unwound and retensioned, we run a safety pass of each tape to ensure stability and performance, as well as providing us a quality control version of your recording to compare with your transfer to make sure we have achieved consistent playback without dropouts and that any issues with the recording are proven to be in the recording and not in the transfer. We also use this QC pass to set optimal levels in each channel of multitrack recordings using mastering quality 2 dB stepped gain and attenuation at the converter level, maximizing your transfer to within the top 6 dB in the digital domain. If all is well, we perform with your ultimate analog-to-digital transfer.

After transfer, we return the tape to a library wind for long-term storage. We do advise that Sticky Shed can recur over time; if you need future transfers, re-baking may be necessary.

Tape baking isn’t a one-size-fits-all process. We have:

Before you consider a DIY approach, remember that inexperienced baking can permanently damage your irreplaceable masters. At Sonicraft, baking is included in our per-reel rates—so there’s no extra charge.

If you notice any of these issues, stop playing the tape immediately and get in touch with us for a professional evaluation.